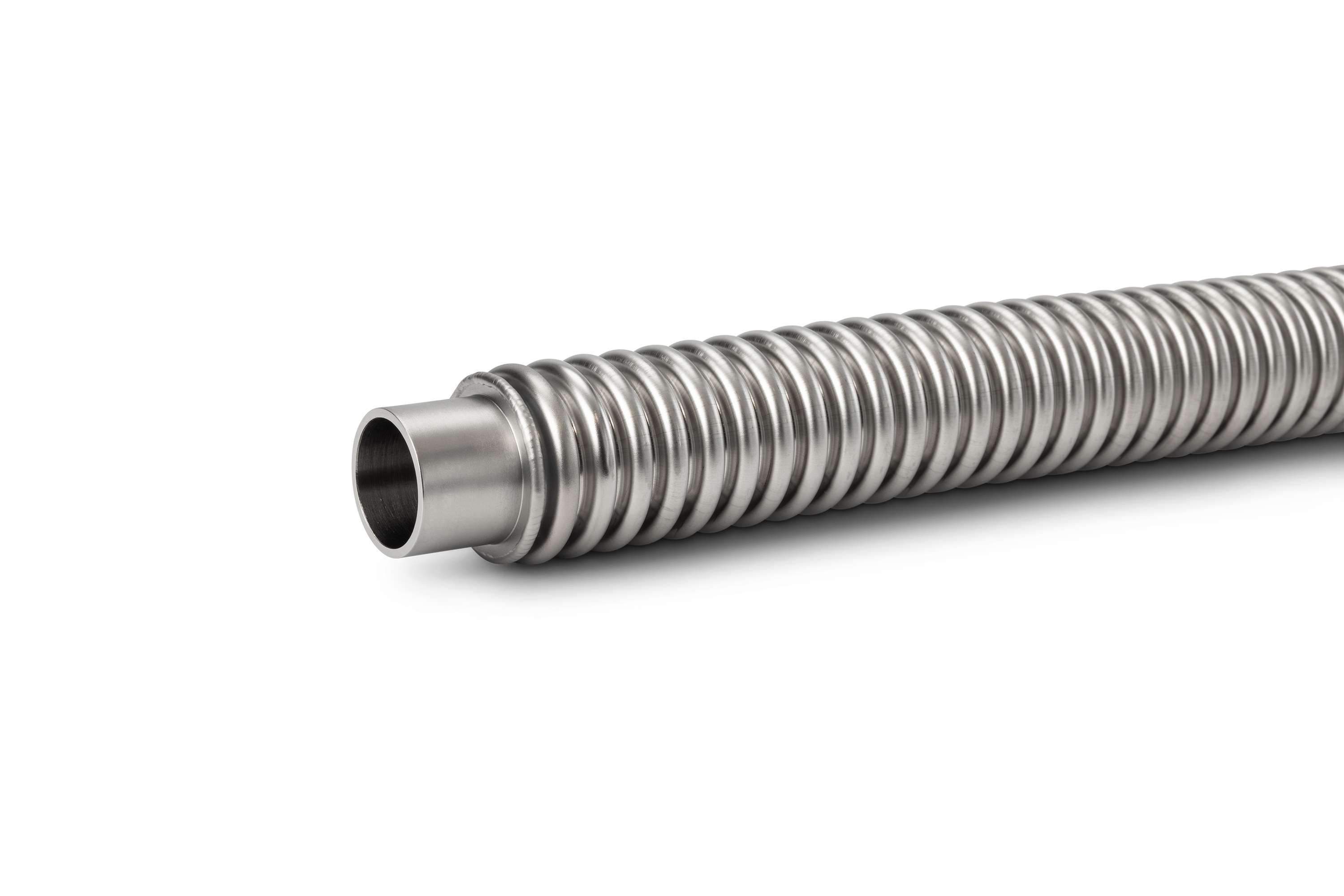

Mamba Parnor® Non-braided

Mamba Parnor® Non-braided

With our products we ensure you of

Diameter [DN]

6

8

10

12

15

20

25

32

40

50

65

80

100

125

150

Diameter [inch]

1/4"

5/16"

3/8"

1/2"

9/16"

3/4"

1"

1 1/4"

1 1/2"

2"

2 1/2"

3"

4"

5"

6"

Stub outside diameter [mm]

6.35

9.53

9.53

12.7

19.05

25.4

Stub wall thickness [mm]

0.89

0.89

0.89

1.24

1.65

1.65

Hose inner diameter [mm]

6.2

8.5

10.4

12.4

15.4

20.3

25.4

32.3

40.2

50.5

64.9

79.6

101.5

126

149

Hose outside diameter [mm]

9.8

13.6

16.2

18.6

22.5

28.3

34.8

43.3

52.4

64.8

80.9

99.6

126.5

152

174

Static bend radius [mm]

10

14

16

24

29

35

42

51

61

73

89

108

126

147

169

Dynamic bend radius [mm]

Max. allowable pressure at 20 °C [bar]

Burst pressure at 20 °C [bar]

Compliance

- EN ISO 9001 EN ISO 10380 / ASME 31.3

Cleanliness

- Standard deliveries: White room

- Vacuum, Ultra high purity: possible upon request

Packaging

- Each hose is bagged individually and boxed. Longer hoses are coiled, bagged and boxed.

Product tests

- Helium leak test (1×10⁻⁵ std cm3/s)

- Additional options: he leak test 1×10⁻⁹ std cm3/s

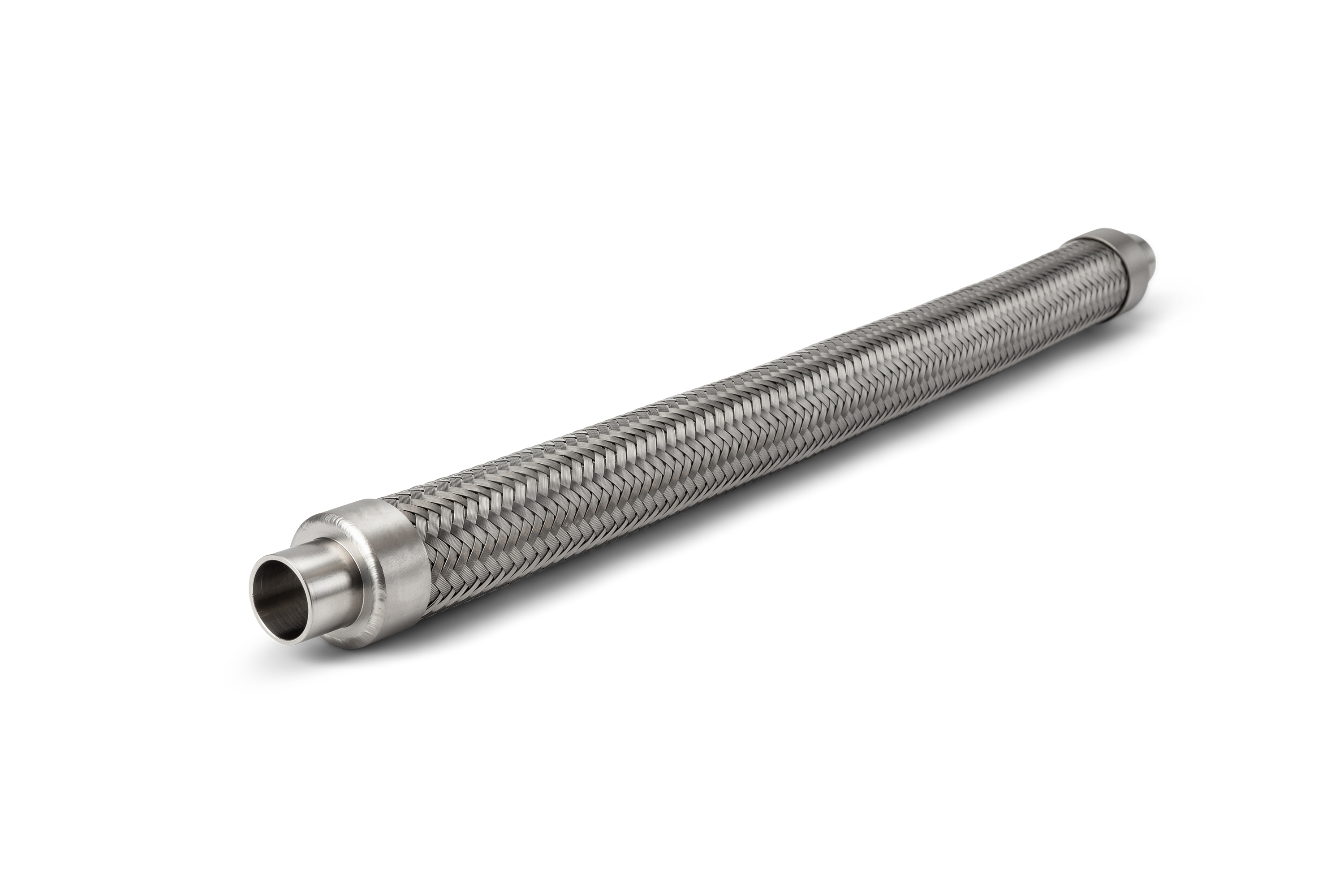

- Smooth surface: ultra high purity and deep vacuum environments

- Excellent choice for both transportation of ultra high purity gases and fluids, and for connecting vacuum spaces when flexibility is required

- Any connector applicable in consultation with our engineers (standard including DIN 11850 weld stubs)

- Temperature range from -273°C to 600°C

Our business is designing and producing artery systems that bring machinery to life

As a manufacturer of flexible hoses and Build-to-Spec and Build-to-Print company for artery systems, we partner with clients to optimize supply chains, minimize time-to-market, and share industry knowledge.