Cobra White PT

Cobra White PT

Double DNs based on market ranges

Smooth bore

Chemical compatibility

Diameter [DN]

6 T

6 P

10 T

10 P

12 T

12 P

20 T

20 P

25 T

25 P

Diameter [inch]

1/4" T

1/4" P

3/8" T

3/8" P

1/2" T

1/2" P

3/4" T

3/4" P

1" T

1" P

Stub outside diameter [mm]

6.35

6.35

9.53

9.53

12.7

12.7

19.05

19.05

25.4

25.4

Stub wall thickness [mm]

0.89

0.89

0.89

0.89

1.24

1.24

1.24

1.24

1.65

1.65

Hose inner diameter [mm]

4.9

6.51

8.1

9.7

10.57

12.95

16.1

19.21

22.2

25.4

Hose outside diameter [mm]

7.65

9.5

11

12.6

13.61

16.1

19.38

22.5

25.78

29.75

Static bend radius [mm]

38.1

76

88.9

127

114

165

152

229

229

305

Max. allowable pressure at 20 °C [bar]

Burst pressure at 20 °C [bar]

Compliance

- EN ISO 9001

Packaging

- Each hose is bagged individually and boxed. Longer hoses are coiled, bagged and boxed.

Cleanliness

- In accordance with CoreDux Standard Cleaning

Product tests

- Hydraulic proof on 100% assembly hose at 70 bars for TA and TB and at maximal working pressure for RF and RM.

- Additional option: air bubble at 15 bars and hydraulic proof with specific pressure asking by customer

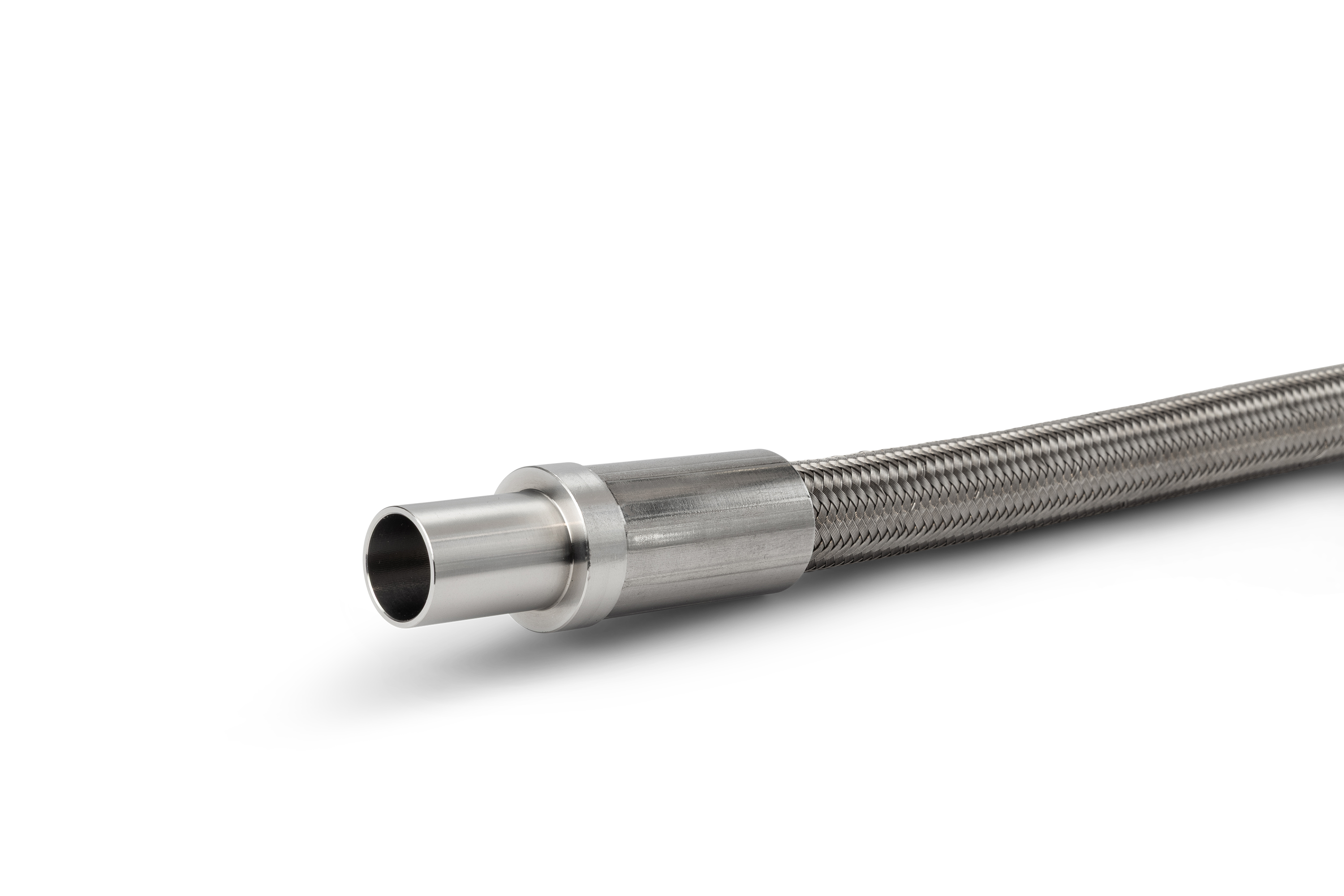

- Tube adapter

- Tube butt weld

- MFSM (male*)

- MFSF (female*)

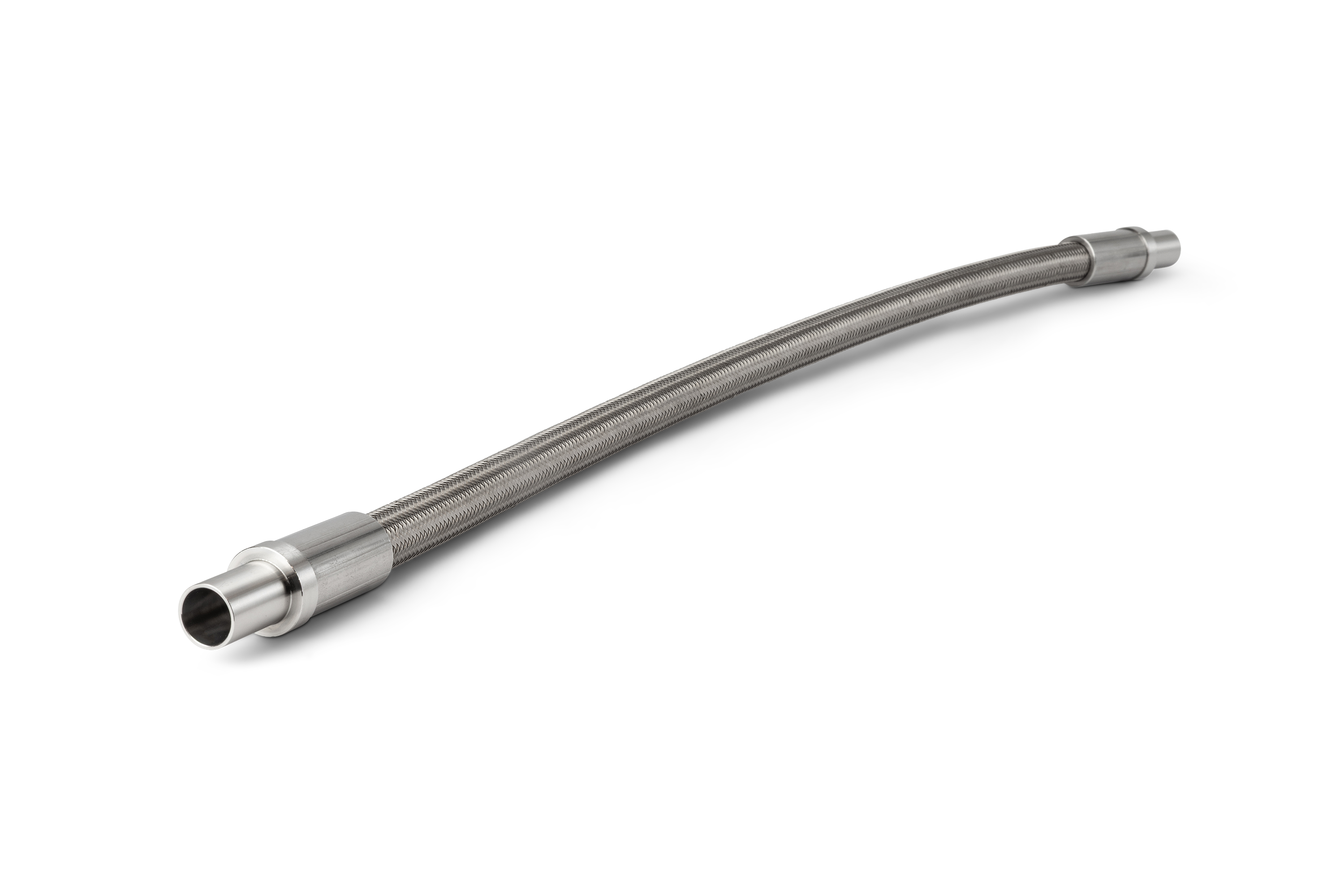

- Stainless steel braided, black-conductive-static dissipating, smooth bore PTFE hose.

- Use case: chemical compatibility and permeation resistance

Our business is designing and producing artery systems that bring machinery to life

As a manufacturer of flexible hoses and Build-to-Spec and Build-to-Print company for artery systems, we partner with clients to optimize supply chains, minimize time-to-market, and share industry knowledge.