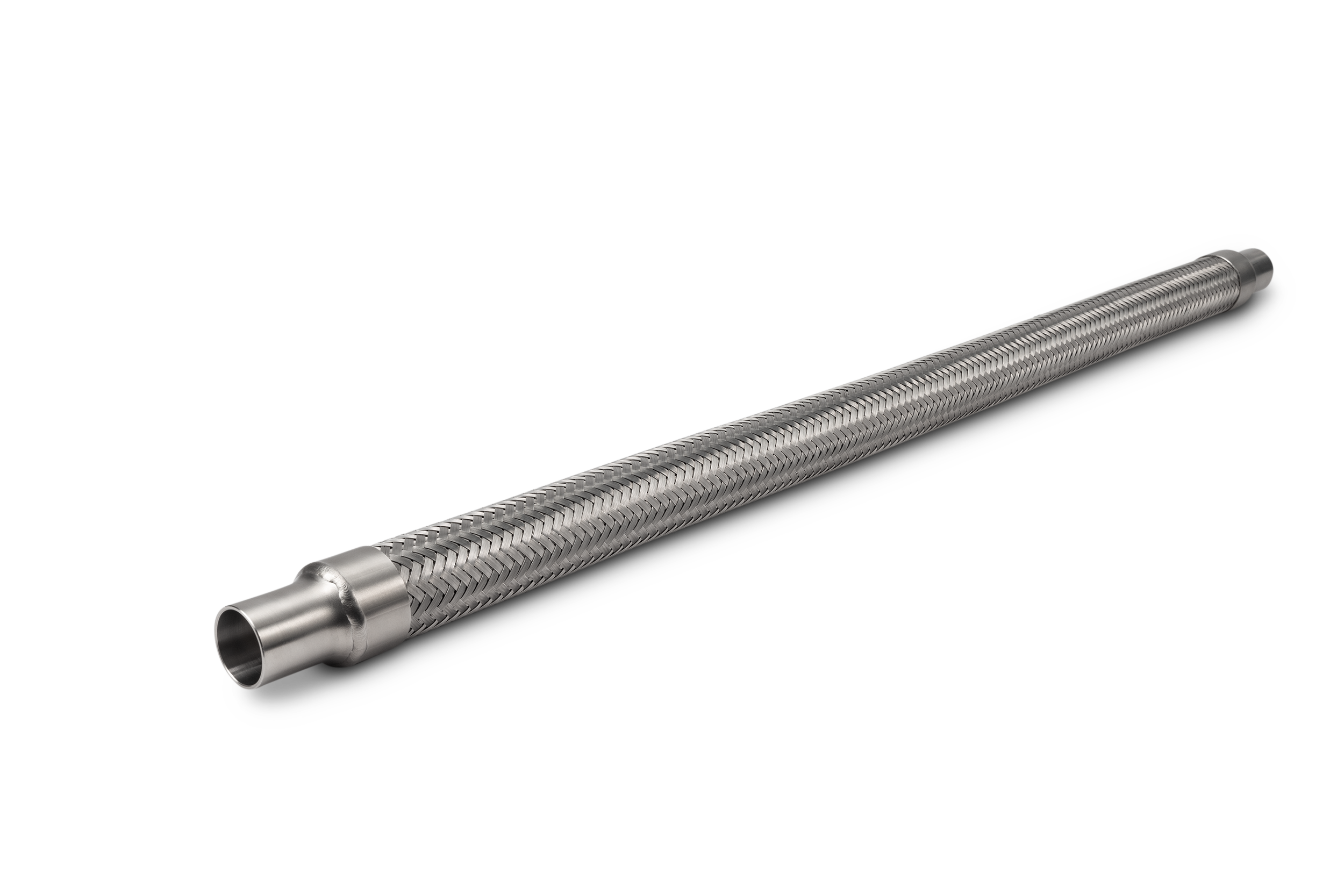

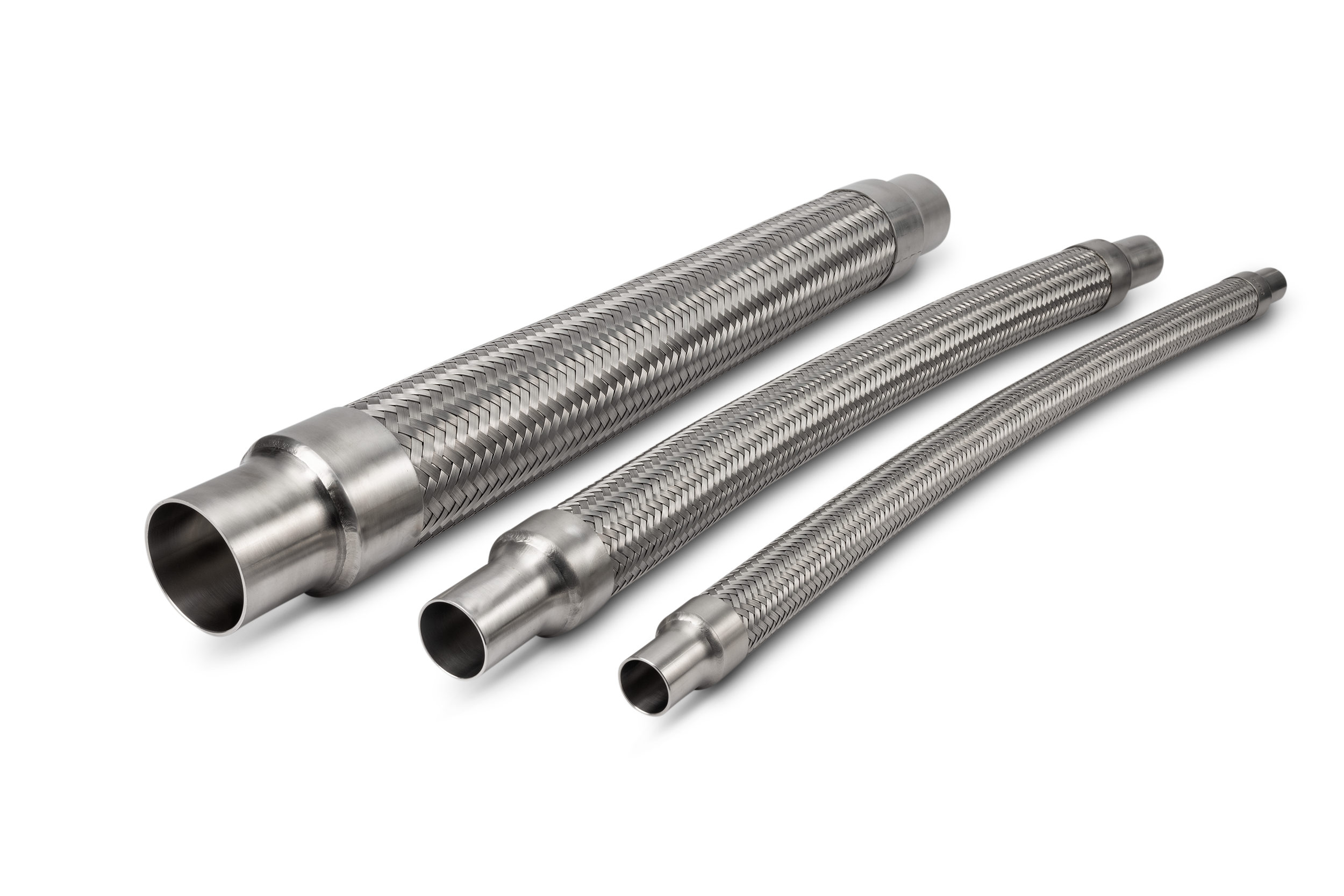

Mamba Diamond Back

Mamba Diamond Back

With our products we ensure you of

Standard EN ISO 1.4404 I AISI 316L (other grades available)

Compliant standards: EN ISO 10380, EN ISO 9001

Clean manufacturing process

Diameter [DN]

Diameter [inch]

1

Diameter [DN]

10

15

20

25

32

40

50

65

Diameter [inch]

3/8

1/2

3/4

1

1 1/4

1 1/2

2

2 1/2

Hose inner diameter [mm]

10.1

15

19.9

24.9

31.8

39.6

49.4

64

Hose outside diameter [mm]

17.8

24.1

30.8

36.4

45.4

54.4

67.3

83.4

Static bend radius [mm]

20

31

38

45

58

70

85

104

Dynamic bend radius [mm]

150

144

169

195

225

255

293

344

Max. allowable pressure at 20 °C [bar]

Burst pressure at 20 °C [bar]

- Standard EN ISO 1.4404 | AISI 316L

- Compliant standards: EN ISO 10380, EN ISO 9001

- Clean manufacturing process

- Use in combination with DIN 11851 couplings (standard including DIN 11851 reihe 2 weld stubs)

- Superior life time up to 50.000 cycles; five times EN ISO 10380 standard

- Excellent for use in extreme environments (-273°C to 600°C)

- Heavy duty stainless steel hose for water purity applications

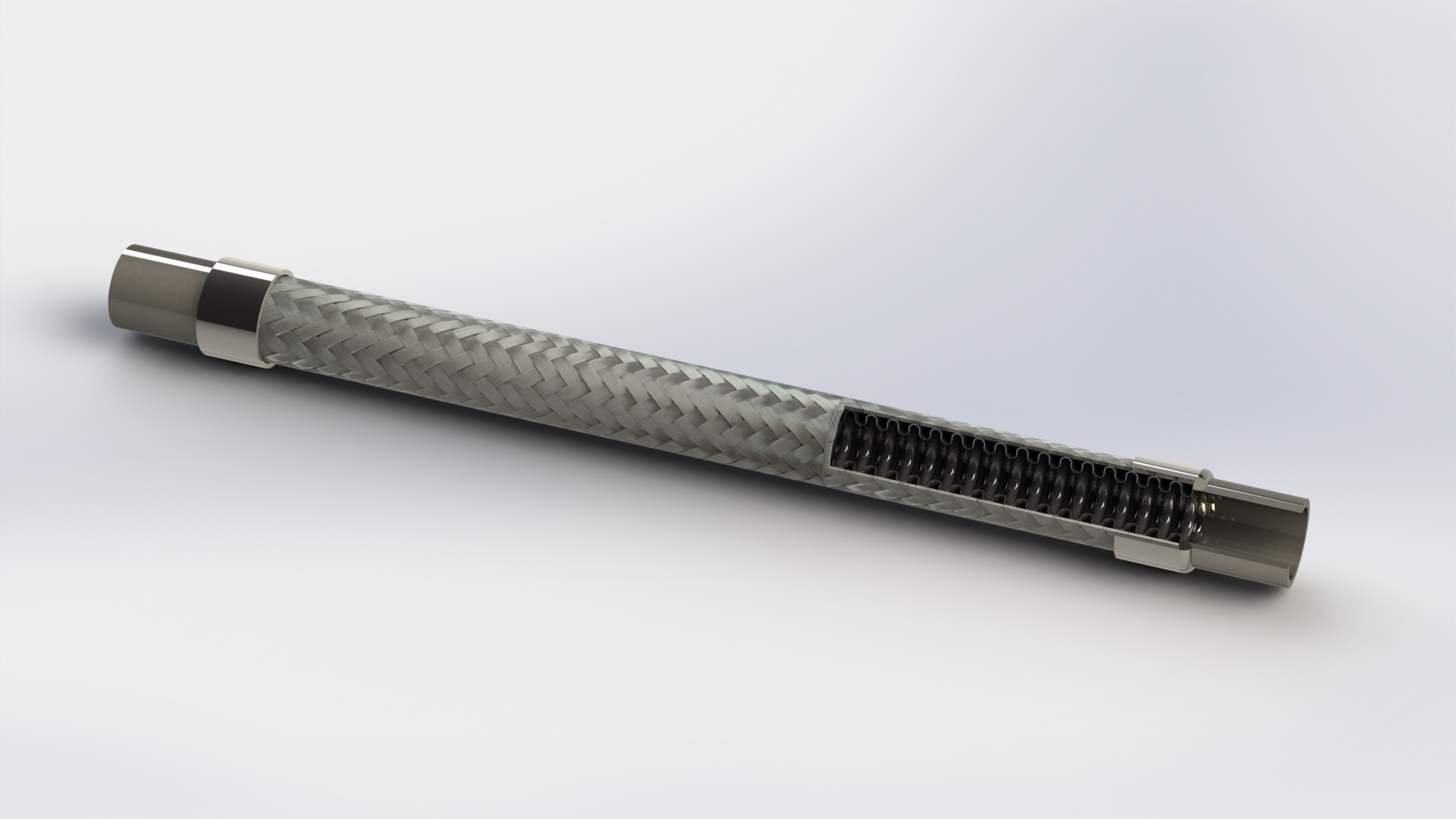

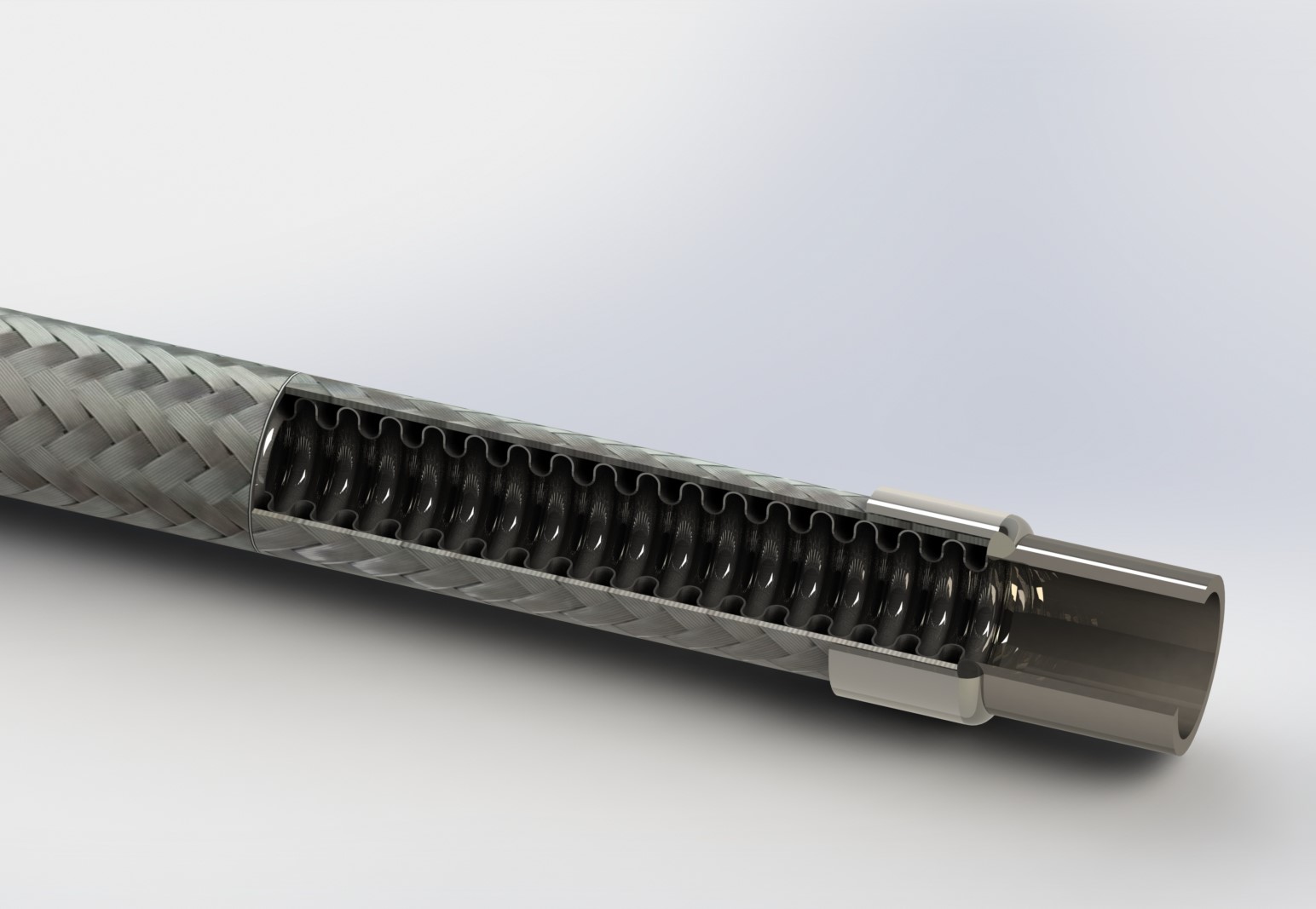

The braided Diamond Back® hose series is manufactured from clean strip material by CoreDux. The stainless steel strip is made into a tube by cold-rolling and high quality continuous longitudinal welding. The highly consistent result is reached by the hydroforming process. This braided Diamond Back® hose series is the excellent choice for transportation of purity fluids. The braided Diamond Back® hose series is compressed for extra flexibility. Even in extreme environments ranging from -273°C to 600°C. The aesthetically pleasing braided type is characterized by its smooth surface and omission of virtual leaks, making it useful in purity fluids and high demanding environments. Other common uses include serving as a protection layer against electromagnetic interference (i.e. Faraday cage), contamination of any kind.

As a manufacturer of flexible hoses and Build-to-Spec and Build-to-Print company for artery systems, we partner with clients to optimize supply chains, minimize time-to-market, and share industry knowledge.