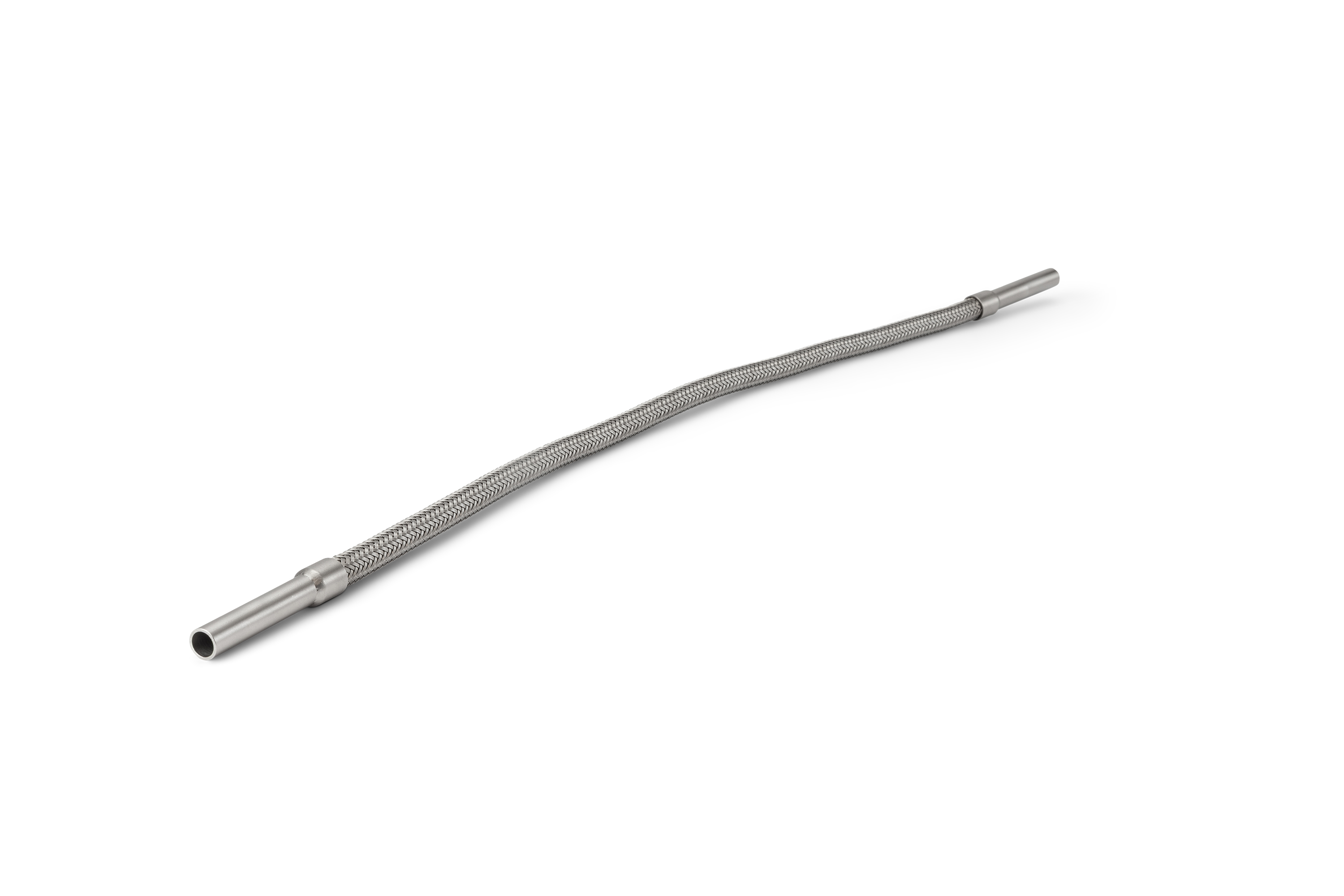

Anaconda DUO®

Anaconda DUO®

With our products we ensure you of

Standard EN ISO 1.4404 I AISI 316L (other grades available)

Compliant standards: EN ISO 10380, EN ISO 9001

Clean manufacturing process

Diameter [DN]

5

6

8

10

12

15

20

25

32

40

50

65

80

100

125

150

200

250

300

Diameter [inch]

Hose inner diameter [mm]

5.2

6.3

8.2

10.2

12.2

16.2

20.2

25.2

32.5

40.3

50.3

65.3

80.4

100.4

126

151

201

252

302

Hose outside diameter [mm]

8.7

9.8

12.4

14.4

17.3

21.3

26.6

31.7

41.1

48.7

61.4

76.4

93.2

113.5

141

166

216

270

320

Static bend radius [mm]

20

25

32

38

45

58

70

85

105

130

160

200

240

290

370

470

700

860

1120

Dynamic bend radius [mm]

75

80

100

115

125

145

170

170

300

340

390

460

520

195

720

720

1200

1520

1520

Diameter [DN]

5

6

8

10

12

15

20

25

32

40

50

65

80

100

125

150

200

250

300

Diameter [inch]

Hose inner diameter [mm]

5.2

6.3

8.2

10.2

12.2

16.2

20.2

25.2

32.3

40.3

50.3

65.3

80.4

100.4

126

151

201

252

302

Hose outside diameter [mm]

9.9

11

13.6

15.6

18.5

22.9

28.3

33.3

42.7

51.1

63.4

78.4

96.4

115.9

143.9

168.4

220.8

274

324

Static bend radius [mm]

20

25

32

38

45

58

70

85

105

130

160

200

240

290

370

470

700

860

1120

Dynamic bend radius [mm]

75

80

100

115

125

145

170

170

300

340

390

460

520

170

820

820

1800

2280

2280

Diameter [DN]

5

6

8

10

12

15

20

25

32

40

50

65

80

100

125

150

200

250

300

Diameter [inch]

Hose inner diameter [mm]

5.2

6.3

8.2

10.2

12.2

16.2

20.2

25.2

32.3

40.3

50.3

65.3

80.4

100.4

126

151

201

252

302

Hose outside diameter [mm]

11.1

12.1

14.8

16.8

19.7

24.5

29.9

34.9

44.3

52.3

64.4

81.2

98.8

120.7

148.7

172

222

278

326

Static bend radius [mm]

20

25

32

38

45

58

70

85

105

130

160

200

240

290

440

550

770

1000

1320

Dynamic bend radius [mm]

120

140

165

190

210

250

285

325

380

430

490

580

660

325

960

960

2000

2500

3250

Optional leak tightness validations

Depending on hose configuration, the following leak tightness validations are available:

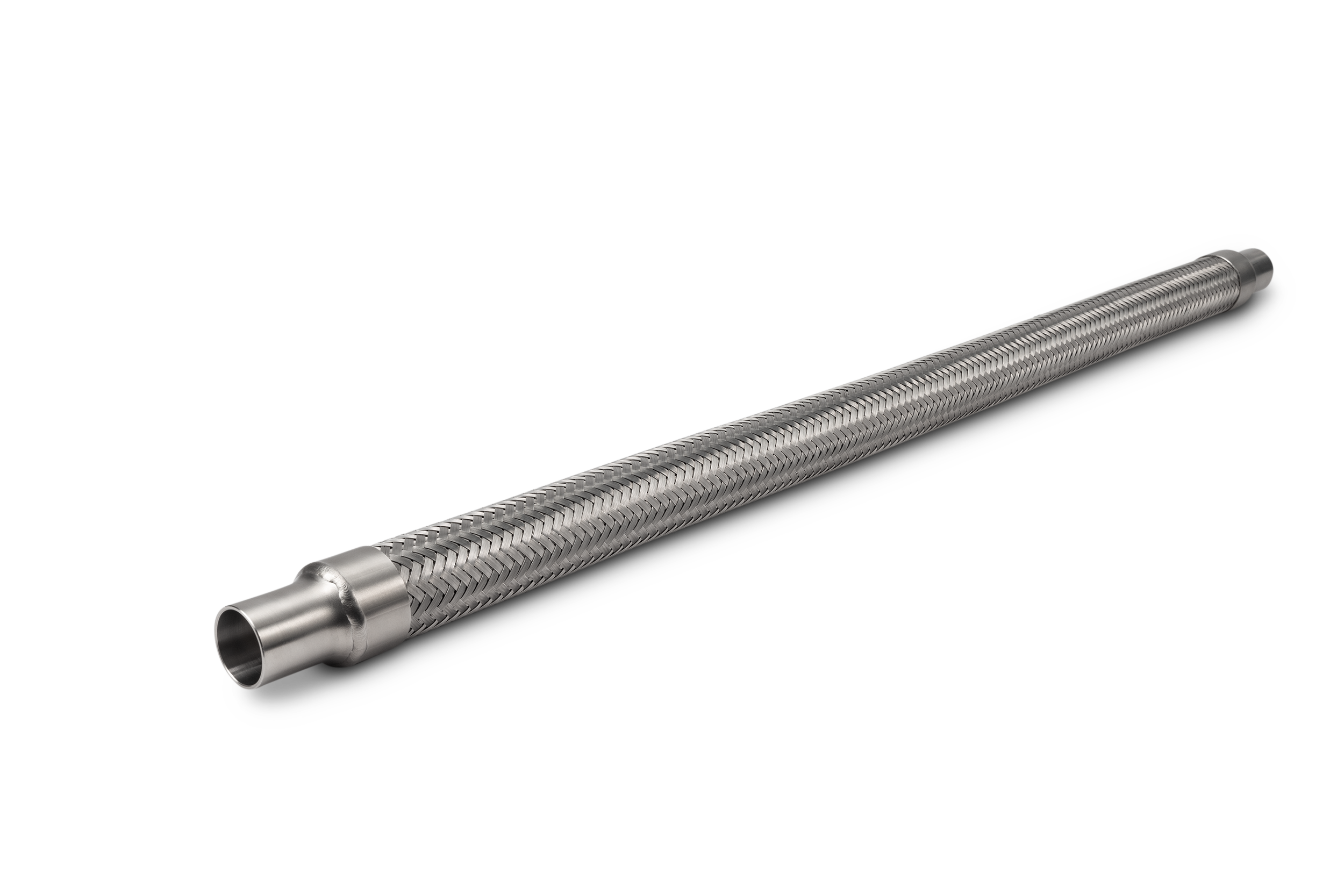

- All kinds of high pressure applications

- Universal vibration absorber

- Engine construction, pumps, compressors

- All kinds of pressure pipes for heavy-duty service with extreme working conditions

Optional leak tightness validations

Depending on hose configuration, the following leak tightness validations are available:

- All kinds of high pressure applications

- Universal vibration absorber

- Engine construction, pumps, compressors

- All kinds of pressure pipes for heavy-duty service with extreme working conditions

Optional leak tightness validations

Depending on hose configuration, the following leak tightness validations are available:

- All kinds of high pressure applications

- Universal vibration absorber

- Engine construction, pumps, compressors

- All kinds of pressure pipes for heavy-duty service with extreme working conditions

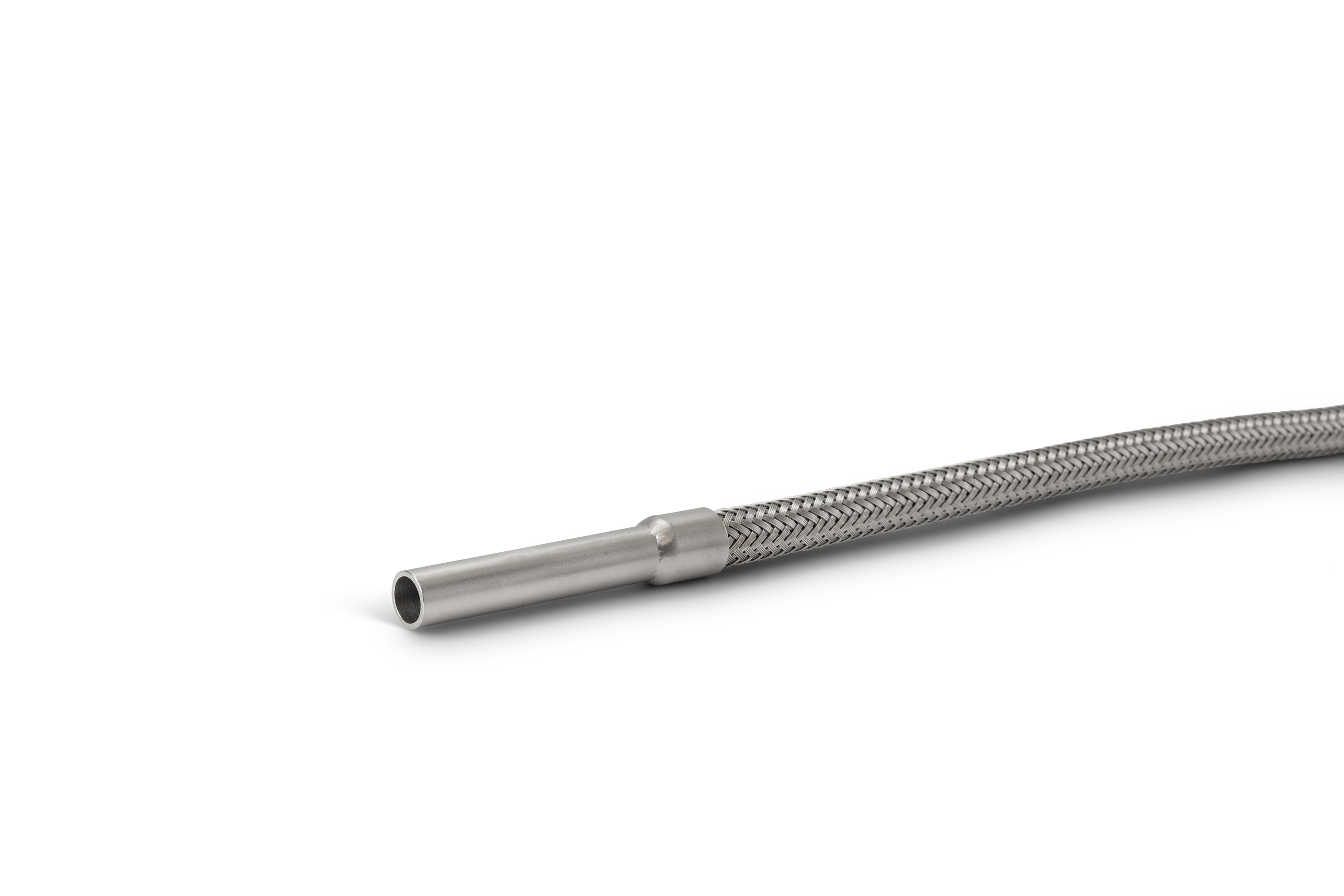

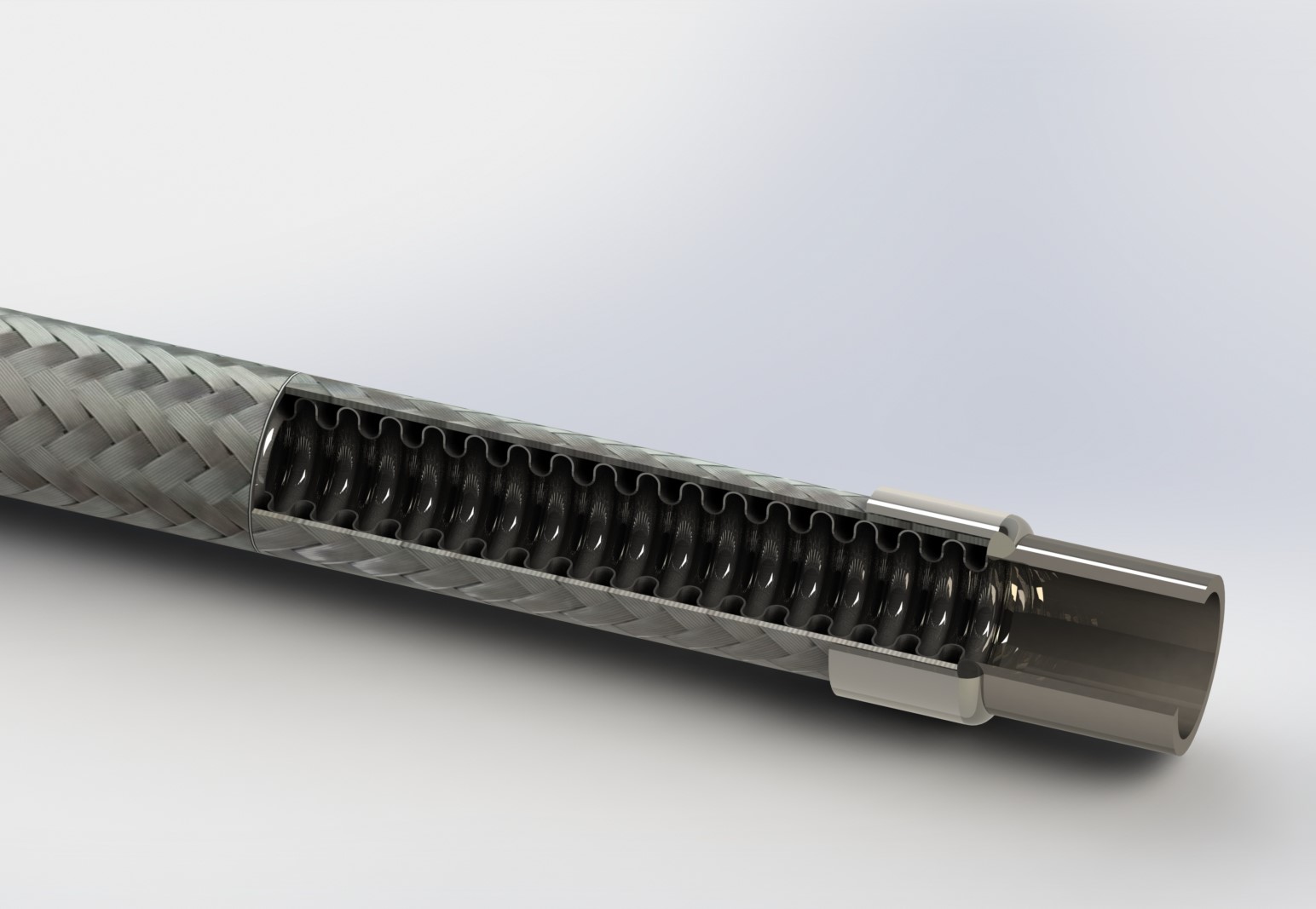

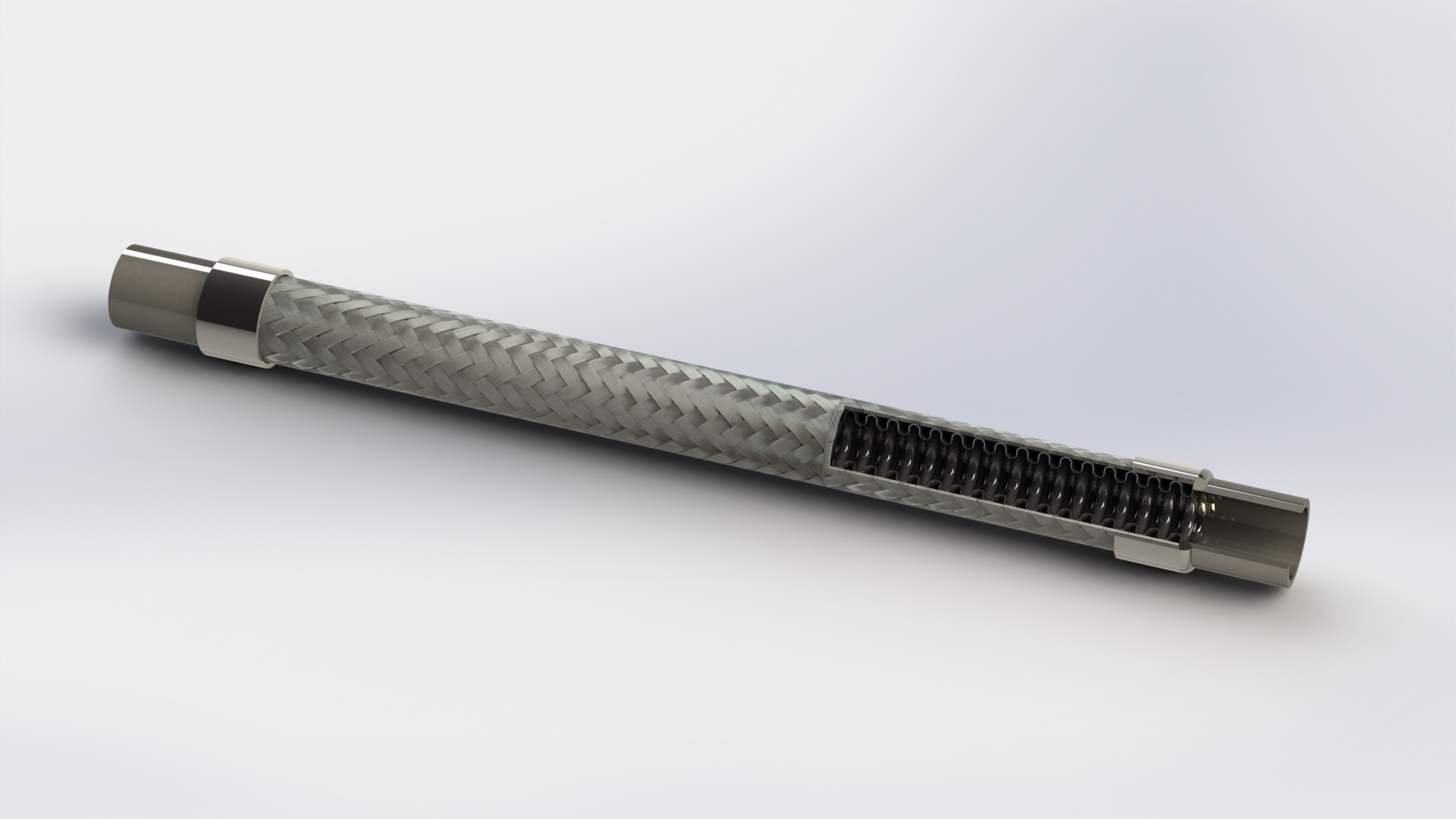

- Outer corrugated hose: stainless steel 1.4571 (similar to AISI 316 Ti)

- Braid: stainless steel 1.4301 (similar to AISI 304)

- Design and type approval in accordance with ISO-10380 standard

- Temperature range: -273°C to 500°C

- Outer corrugated hose: stainless steel 1.4571 (similar to AISI 316 Ti)

- Braid: stainless steel 1.4301 (similar to AISI 304)

- Design and type approval in accordance with ISO-10380 standard

- Temperature range: -273°C to 500°C

- Outer corrugated hose: stainless steel 1.4571 (similar to AISI 316 Ti)

- Braid: stainless steel 1.4301 (similar to AISI 304)

- Design and type approval in accordance with ISO-10380 standard

- Temperature range: -273°C to 500°C

As a manufacturer of flexible hoses and Build-to-Spec and Build-to-Print company for artery systems, we partner with clients to optimize supply chains, minimize time-to-market, and share industry knowledge.