Purification

Purification

- We specialize in engineering and manufacturing ultra-clean metal and PTFE hoses for high-purity industries and can comply with cleanliness standards such as EIGA, EN 12 300, and VDA, or Aerospace cleaning standards such as Class 0 or SEA A611.

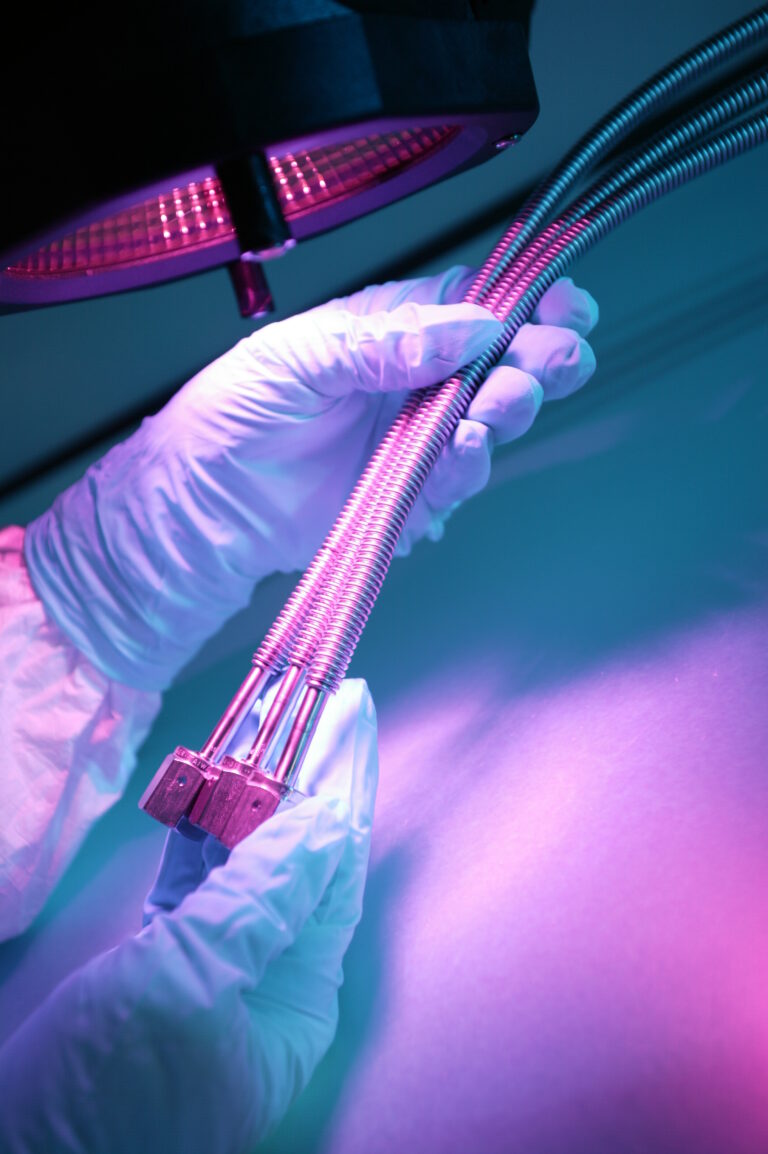

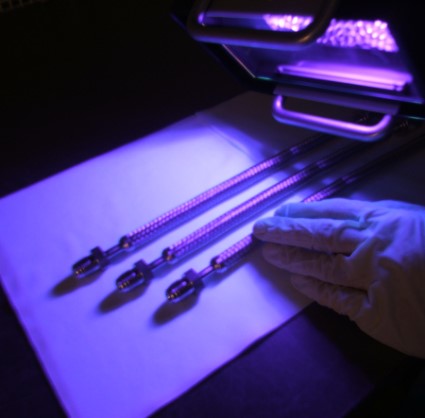

- Our state-of-the-art laboratories and clean rooms for building and testing hoses under strict clean conditions use a unique cleaning process and agent to validate their products.

- The capability to design, engineer, and manufacture ultra-high purity and ultra-high vacuum hose systems to solve the most complex challenges for customers worldwide.

Your challenges, engineered to precision

“I’m searching for a metal hose assembly to achieve an ultra-clean vacuum cleanliness. Is this something you can achieve?” Definitely! High-pressure vacuum hoses are our forte; even better, we will follow any cleanliness guidelines you require, from flushing and ultrasonic cleaning to baking out pollutants. Nothing is beyond our means. We know that keeping your equipment, machine, and process ultra-clean can often be a challenge. That is why we utilize state-of-the-art laboratories and clean rooms to ensure our metal hoses are built and tested under the strictest clean conditions.

Whatever standards you need

Furthermore, we have developed a highly specified cleaning process and a specially-formulated cleaning agent, which is the best in the business. This is how we validate our products and supply you with an exemplary cleaning report as validation. EIGA Industrial Gases Council, EN 12 300 Cleanliness for cryogenic containers, the renowned VDA of the automotive world – whatever standards you need, we can comply. The benefits for you? No alien materials in your system – not even molecules or particles. Therefore, less risk of contamination ensures the safe, efficient, and cost-effective transportation of liquids and gas.

A glimpse of our new premises

One of the key advantages of metal hoses is their ability to handle extreme conditions. They are capable of withstanding high temperatures, making them suitable for applications involving hot gases or fluids. Metal hoses are also highly resistant to pressure, allowing them to handle high-pressure applications, such as hydraulic systems or industrial processes that involve the transport of fluids under substantial force.