Semiconductor Industry

Gas, liquid and vacuum applications for semiconductor equipment Our focus segments within Semicon ‘front-end’ wafer manufacturing are lithography, etching, deposition, ION implant, metrology & defectivity and optics.No permeation and no contamination.

Guaranteed.

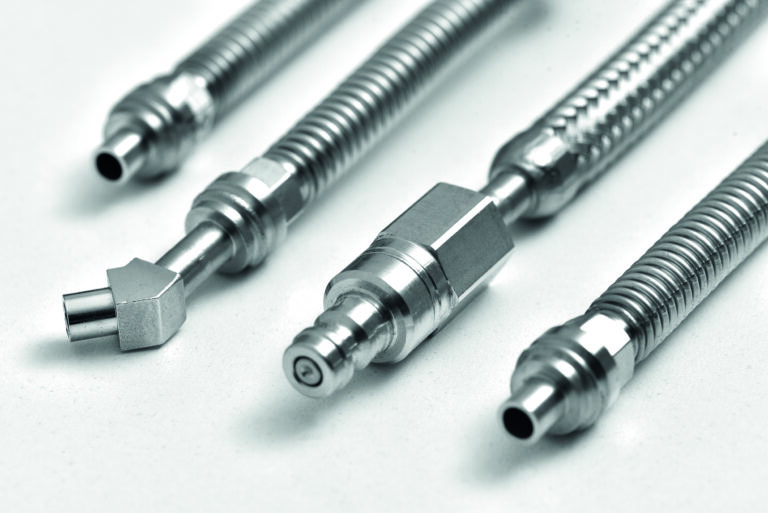

Are you a semiconductor industry specialist seeking an engineering partner fluent in your language? Look no further. As vacuum solution experts, we collaborate with you to design and engineer customized stainless steel metal hoses and artery systems. Wondering about vacuum chamber use, impact on applications, or reaction forces under specific vacuum and/or corrosive gaseous conditions? We have your answers. At CoreDux, we guarantee reliable, vacuum-compatible connecting parts tailored to your needs. Our full-service approach includes feasibility checks, design improvements, and expert engineering with precise welding techniques. Benefit from cost-effective, lifetime-lasting solutions that are meticulously tested and cleaned. Plug and play with CoreDux, your reliable partner in delivering exactly what you need. Proud member of the Brainport Industries network.

Why CoreDux?

Partner with us for ultra-safe, durable hoses tailored precisely to your needs. Whether it’s leveraging our expertise or simply having a conversation with experienced professionals who understand the ins and outs of gas and liquid transportation, we’re here for you. No need to worry; we’re not your run-of-the-mill manufacturer. As the only fully integrated ODM and B2S/B2P system integrator company globally, we’re equipped to efficiently address all your gas, liquid and vacuum transportation needs. From design to manufacturing and assembly, it’s all handled in-house – no intermediaries, no hassle.

CoreDux Components

Catalog items and standardized parts that fit

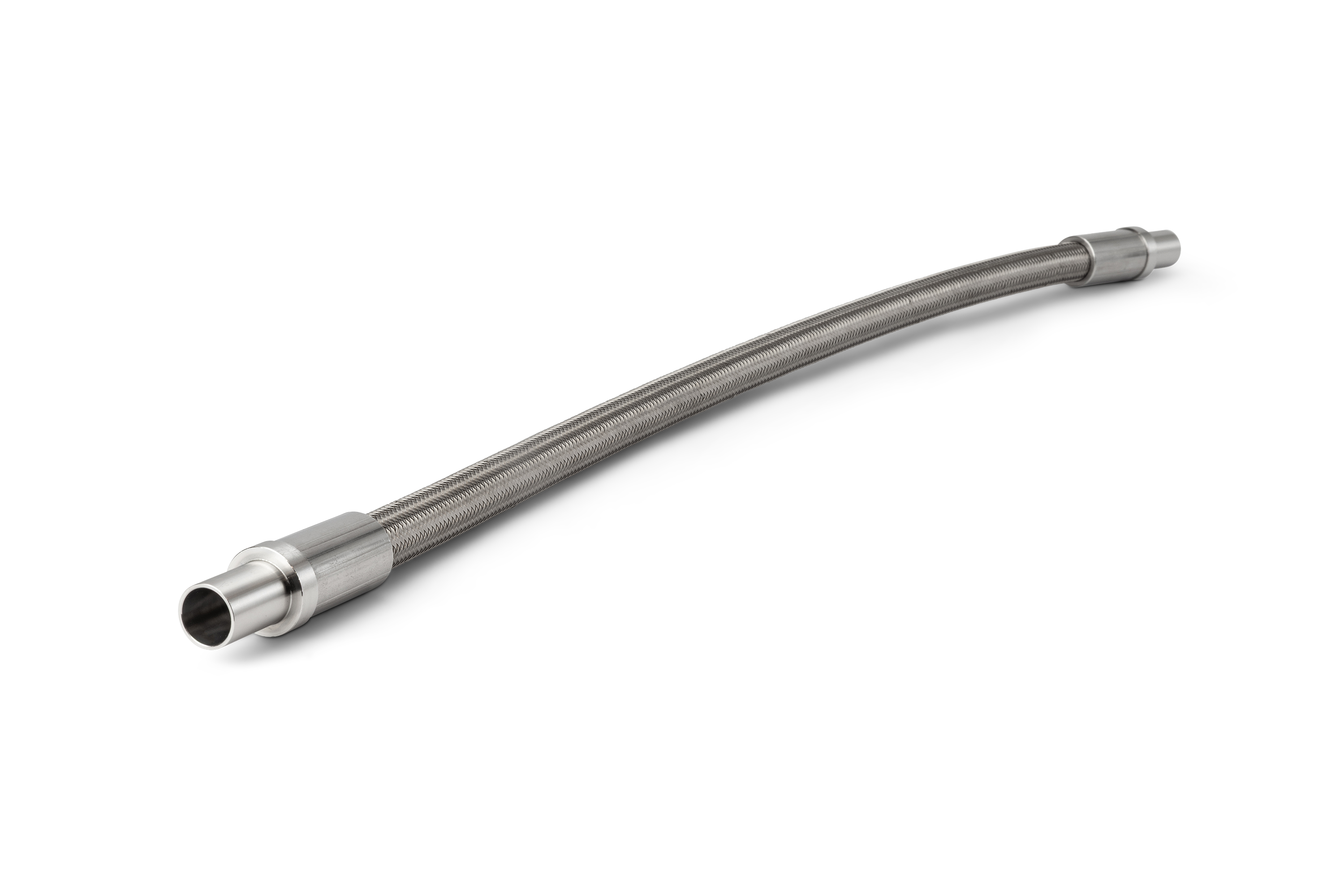

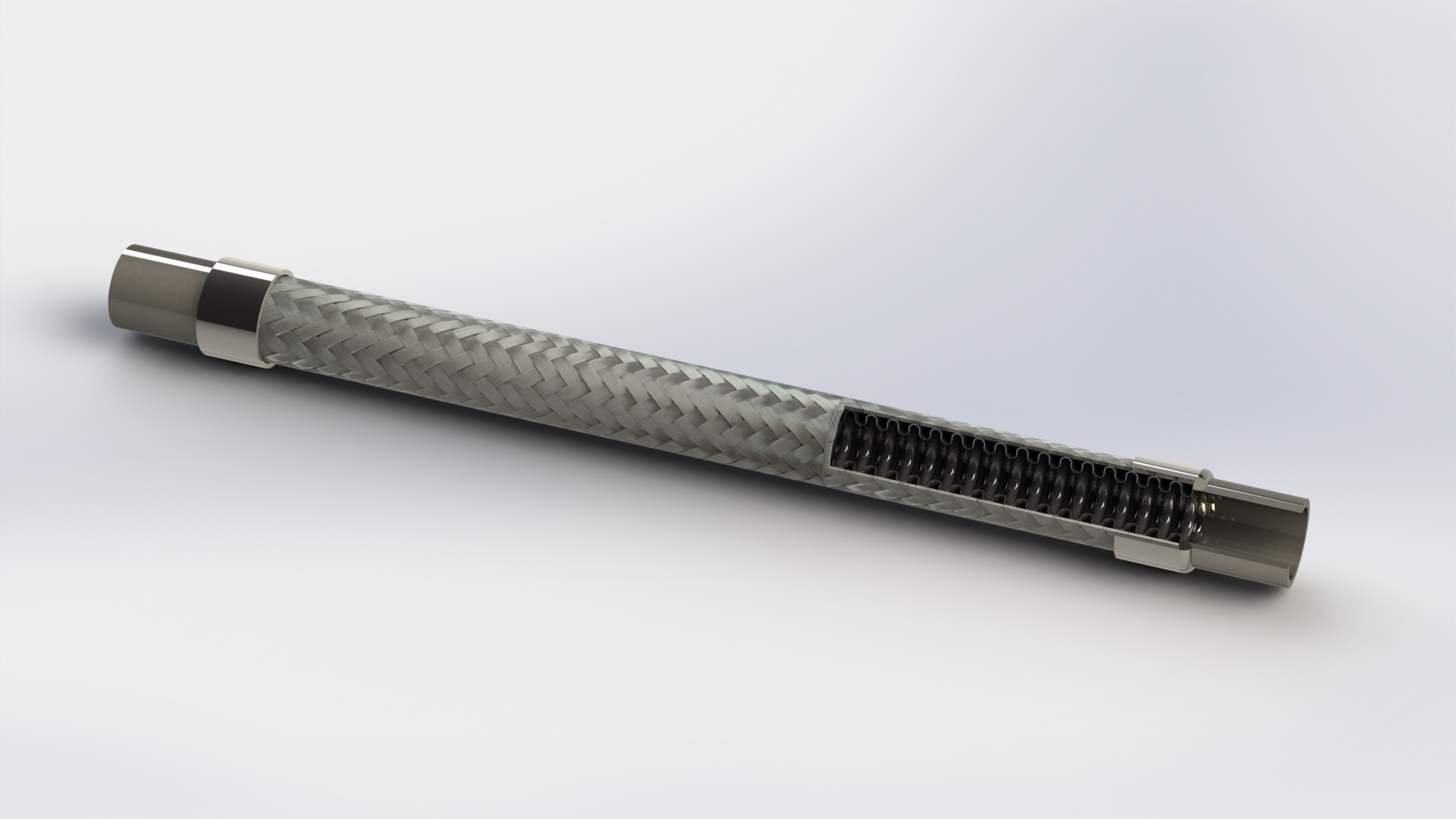

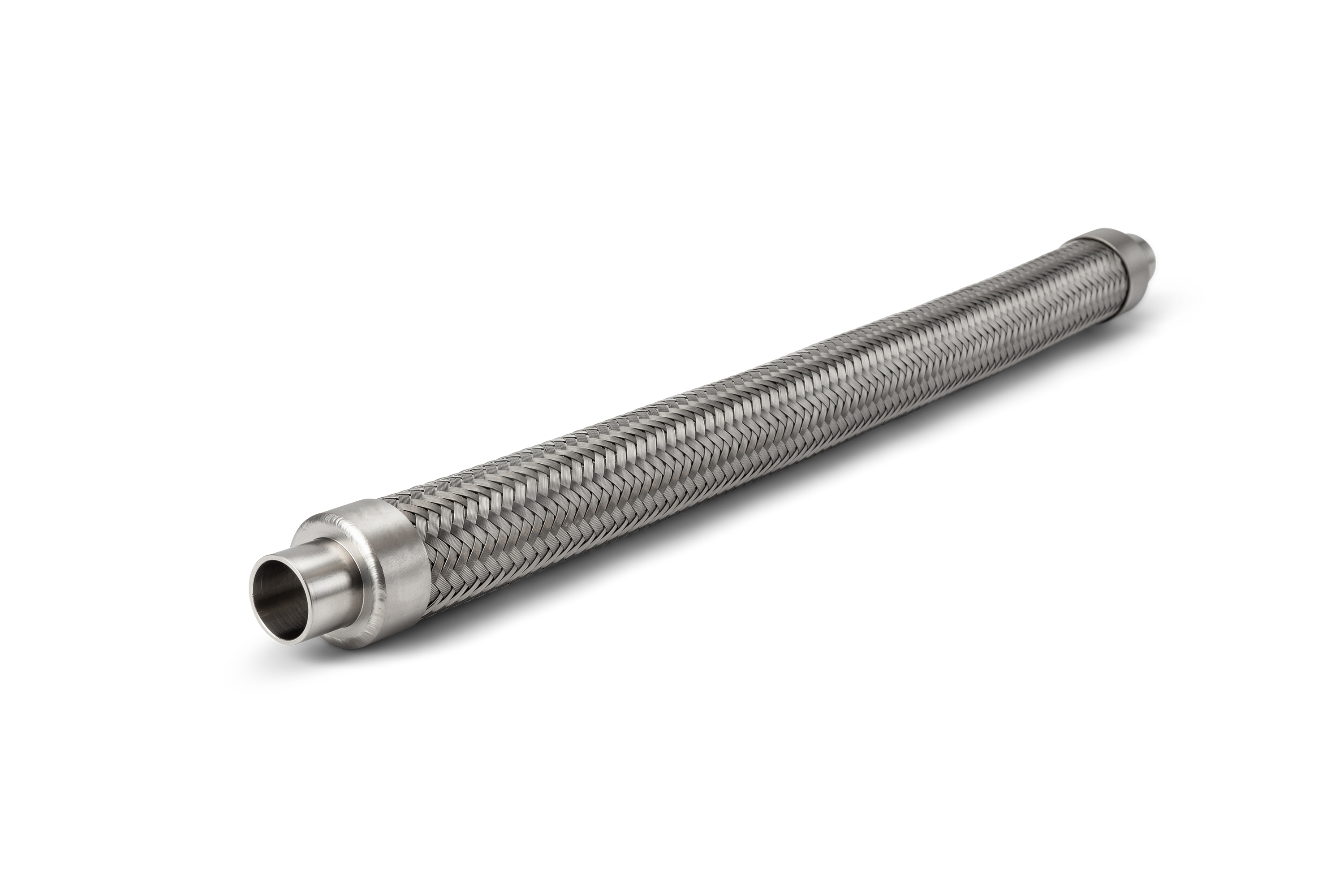

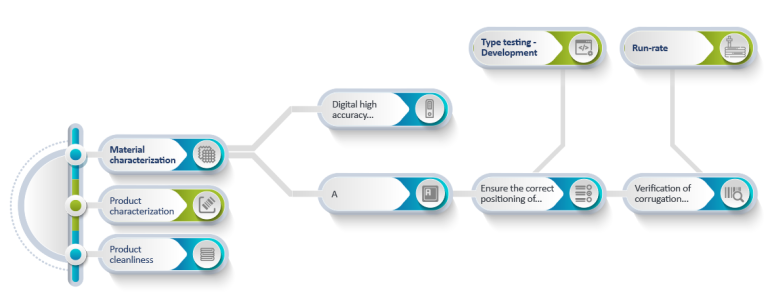

Ranging from a well-developed standard portfolio to original equipment- and design manufacturing, We strive to be your go-to manufacturer for flexible components. As an ODM, we develop highly specific products catered to your application needs. Our product development and process roadmaps enable flawless manufacturing of tailor-made or system-specific parts.

Integrated solutions

From contract manufacturing to systems integration

As a built-to-print or built-to-spec manufacturer, we offer both contract manufacturing and full systems integration. This means that depending on your needs and wishes, we can provide design and manufacturing or focus on the latter.

When these come together

Dual Competence, Single Source

Our sweet spot lies where we use CoreDux components to provide your systems integration. It is in this vertically integrated ODM that we offer the most value. As an ODM for our CoreDux standard portfolio and our proposition as a systems integrator, we have the skills, capabilities, and processes in-house to solve your challenges. We call this Dual Competence, Single Source.

Technical Challenges

Solving common design challenges by collaborating with you to engineer and manufacture customized stainless steel and PTFE hoses and artery systems.

Technical Challenges

Enabling technologies

From standard components to full systems integration

Whether you’re looking for a component that fits or full-scale contract manufacturing, CoreDux has the skills and capabilities to help you move forward and fulfil all your needs in-house. Generally speaking, we distinguish two working methods. Read the paragraphs below to find out what that means.

What’s in it for you?

We have mapped out the challenges you might face and the skills and capabilities we offer to secure and assure you.

Our knowledge

Engineer-to-engineer

The key to solving problems is viewing them from different angles. At CoreDux, we speak your language and like to share the lessons we’ve learned. Would you like to know more? Download the whitepapers below to get started.

How can we help?

Whether it’s leveraging our expertise or simply having a conversation with experienced professionals who understand the ins and outs of gas and liquid transportation, we’re here for you. No need to worry; we’re not your run-of-the-mill manufacturers. As the only fully integrated ODM and B2S/B2P company globally, we’re equipped to efficiently address all your gas and liquid transportation needs. From design to manufacturing and assembly, it’s all handled in-house—no intermediaries, no hassle.

What our clients say

Testimonial

FAQ's

Any questions?

We’ll try to answer the most common questions below. Is your question not listed below? Please contact our Engineer Hub.

Who/What is CoreDux?

We are an Original Design Manufacturer (manufacturing our own CoreDux hoses with customer-specific adapters) and a B2P System Integrator (building ingenious systems). What gets our hearts racing? Offering a flexible, custom-made service to push boundaries and develop next-generation equipment. We do this by continually advancing the science behind our products and creating never seen artery systems that bring machinery to life.

How can we help you?

Use our knowledge or talk to our experienced engineering experts and find the right solution to the minefield of complex challenges you face in gas and liquids transportation. In the comfort of knowing we are the only full-service ODM and B2P company in the world that can solve all your gas and liquid transportation challenges in one single go. Designing, manufacturing and assembling everything in-house with no third parties involved.

Why Ultra High Purity?

Some systems just need to be very clean and are used in applications outside the machine. This type of high purity piping system is seen to be slightly less critical to an ultra-high purity system, so it therefore needs less validation. These parts need to be ultra clean. No dirt, no grease, no oil, no stains, no particles, no molecules – absolutely nothing. These high purity systems can transport gasses safely and efficiently. You can think of hydrogen, nitrogen, oxygen or helium.

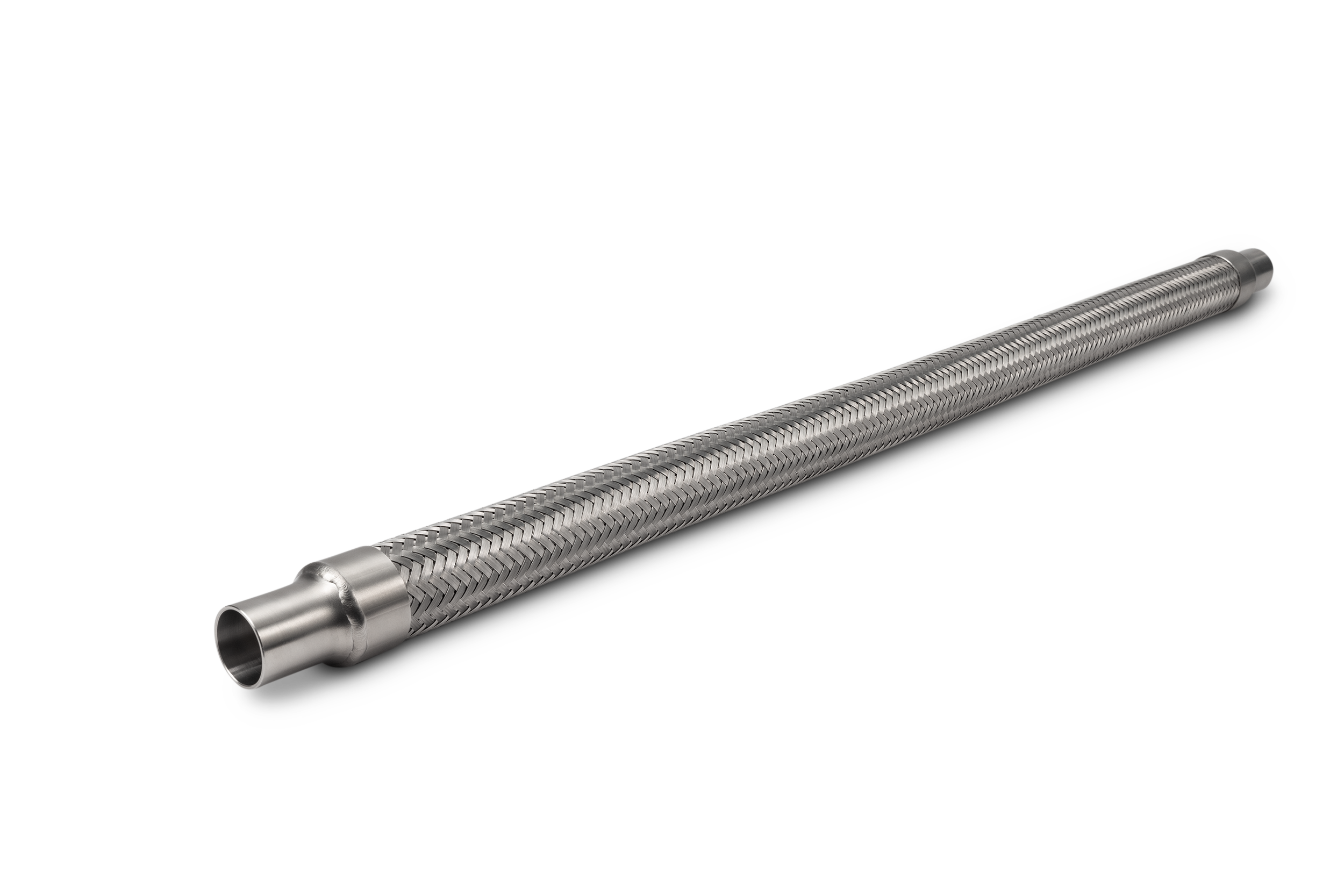

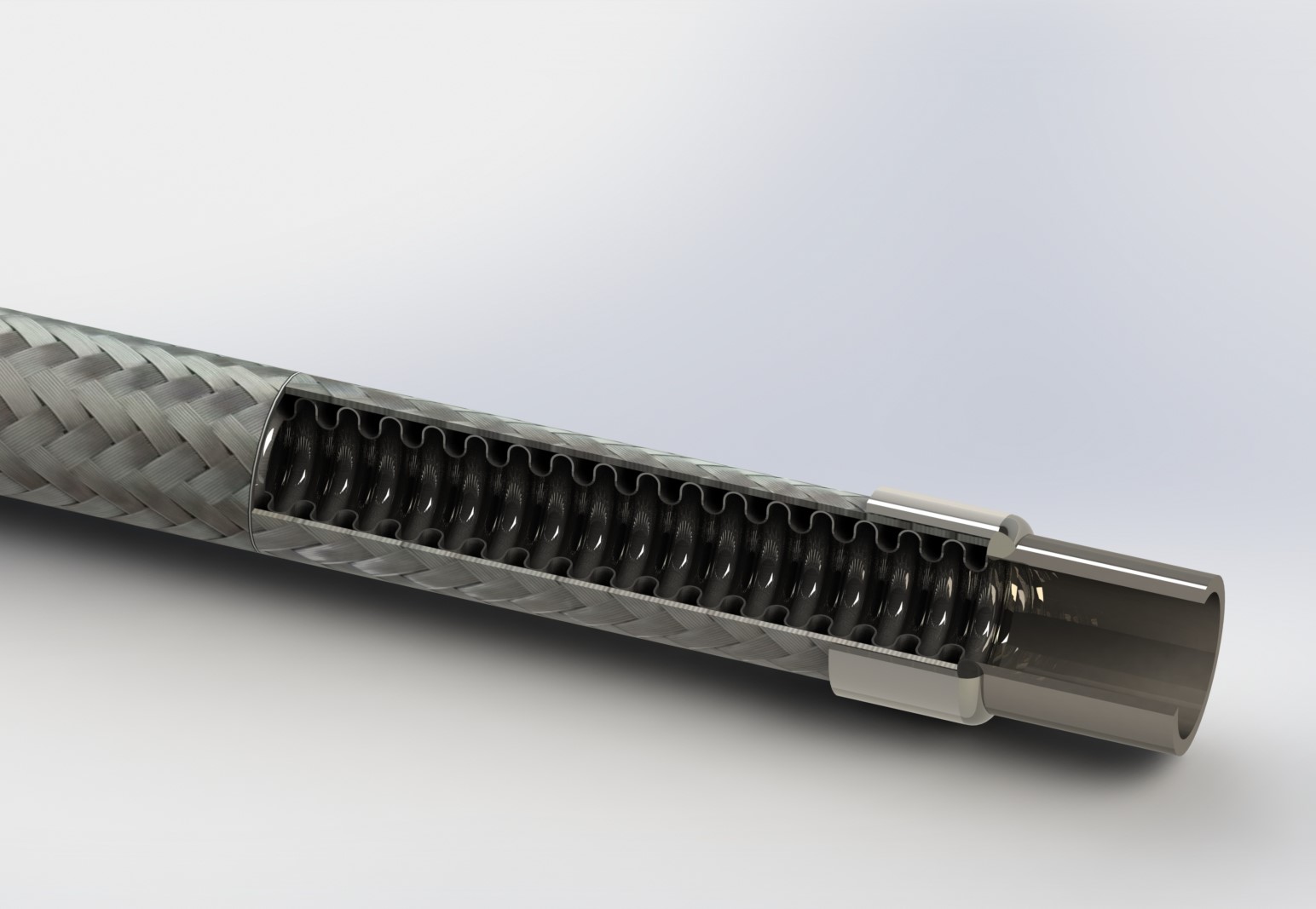

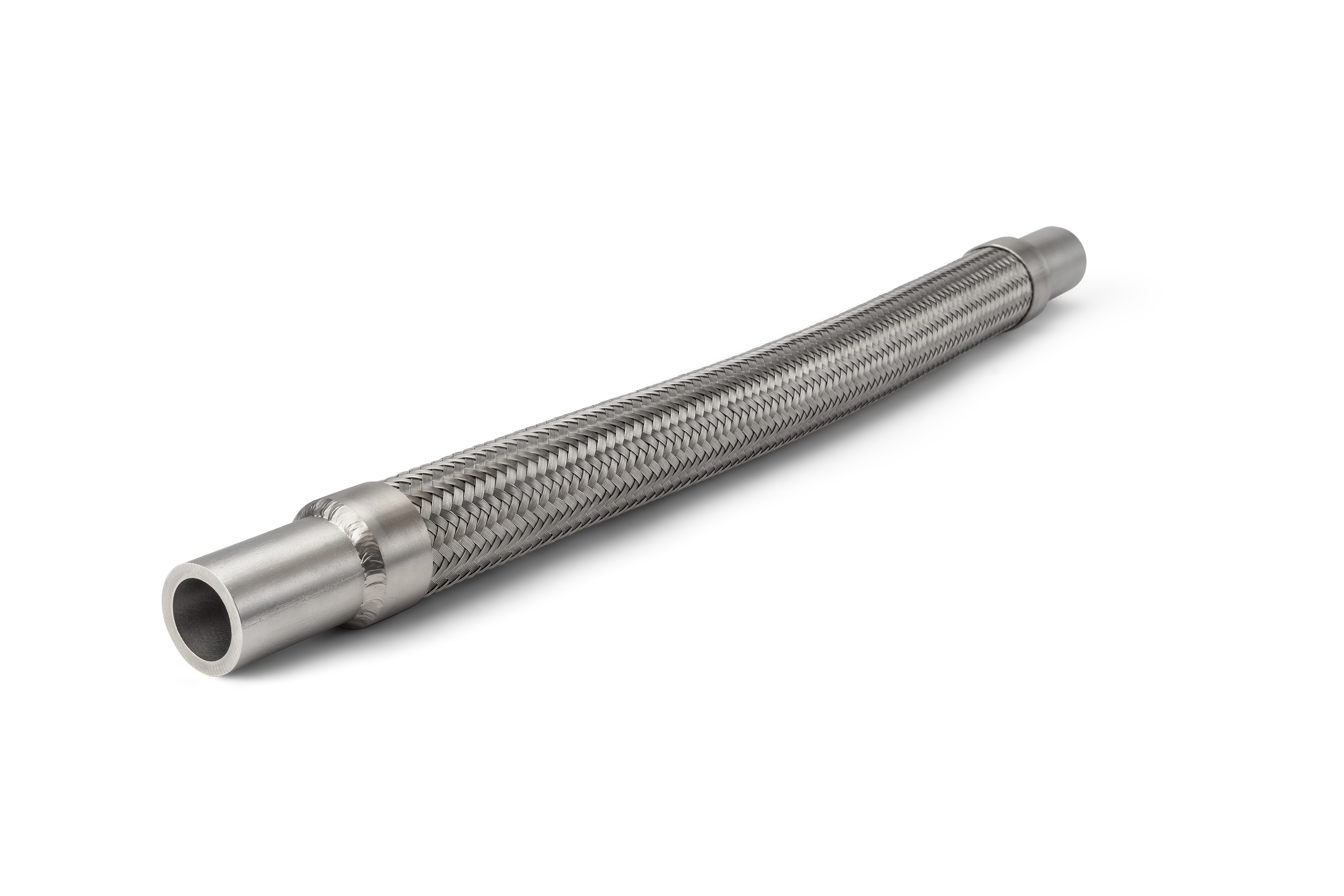

What material does the ultra high purity hose consist of?

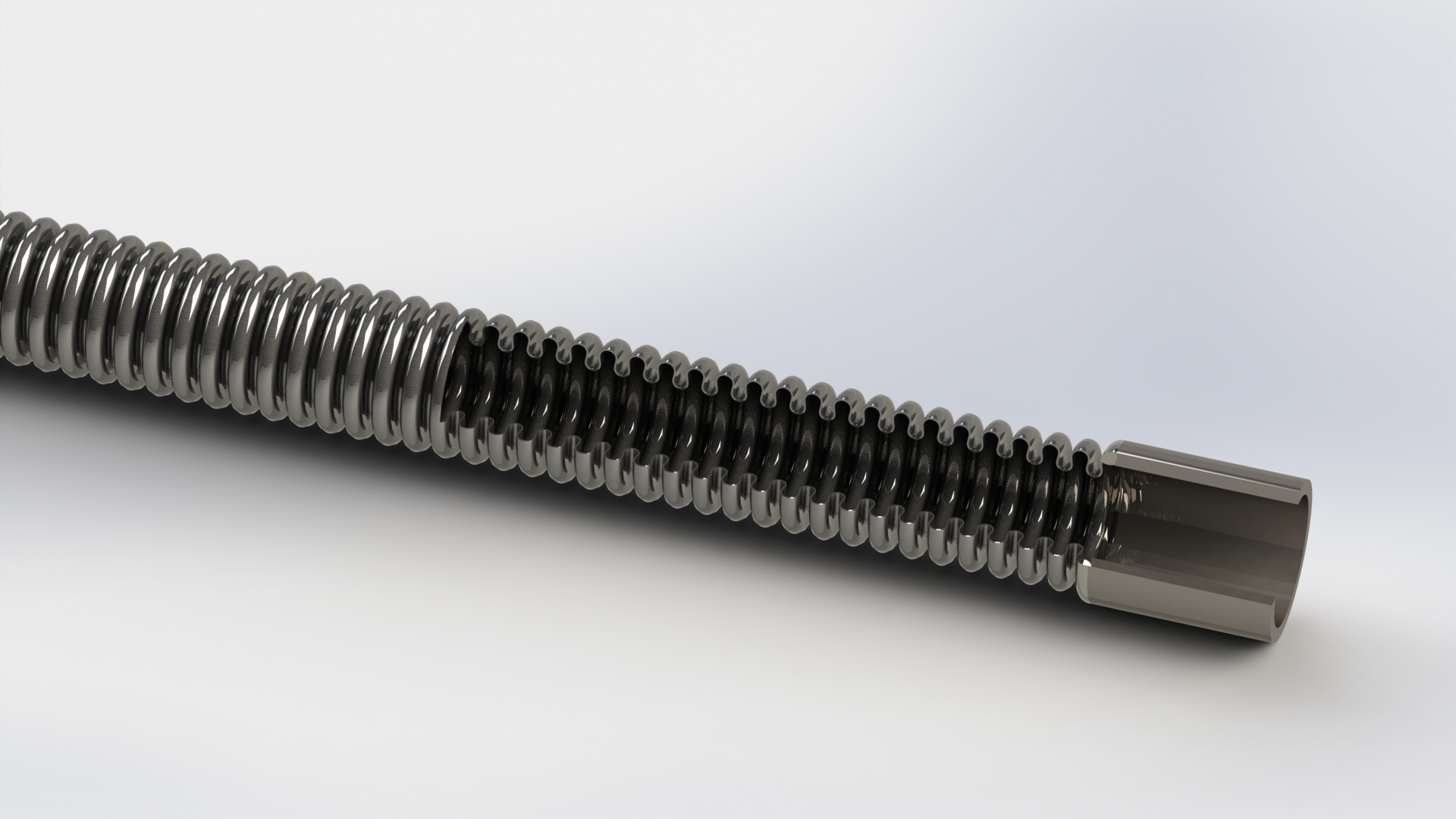

We mostly design, manufacture and use our UHP hose because of the stainless steel convoluted outer hose making ultra-high purity possible on the in- and outside. The inside allows the medium to be clean and safely transported and the convoluted stainless steel on the outside ensures flexibility, protection and no permeation.